40 welding shop safety worksheet

Shop Safety Answer Key Worksheets - K12 Workbook Displaying all worksheets related to - Shop Safety Answer Key. Worksheets are Basic shop safety t u d n t w o r k s h e t, General shop safety, California agricultural teachers essential guide to safety, Basics of welding safety test, Talking safety teaching young workers about job safety, Answer key, Field trip lincoln electric u t d t w o r k s h e t a n, Safety quiz. ICEV Welding Workshop Safety Worksheet.pdf - Welding Shop Safety ... STUDENT WORKSHEET Accompanies: Welding Shop Safety 3Welding Shop Safety 2. Some examples of hazardous materials would be paint, oil,_________________, aerosol cans and even scrap _____________. 3. Check with your __________________ to make sure how to properly dispose ofhazardous materials.

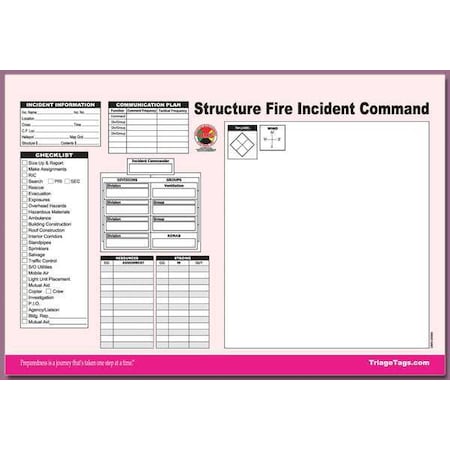

Welding with Arc-Welding Equipment - Safety Checklist | NIOSH | CDC It applies to the use of arc-welding and cutting equipment. This checklist must be used with the Welding, Cutting, and Brazing-General Requirements checklist. The regulations cited apply only to private employers and their employees, unless adopted by a State agency and applied to other groups such as public employees.

Welding shop safety worksheet

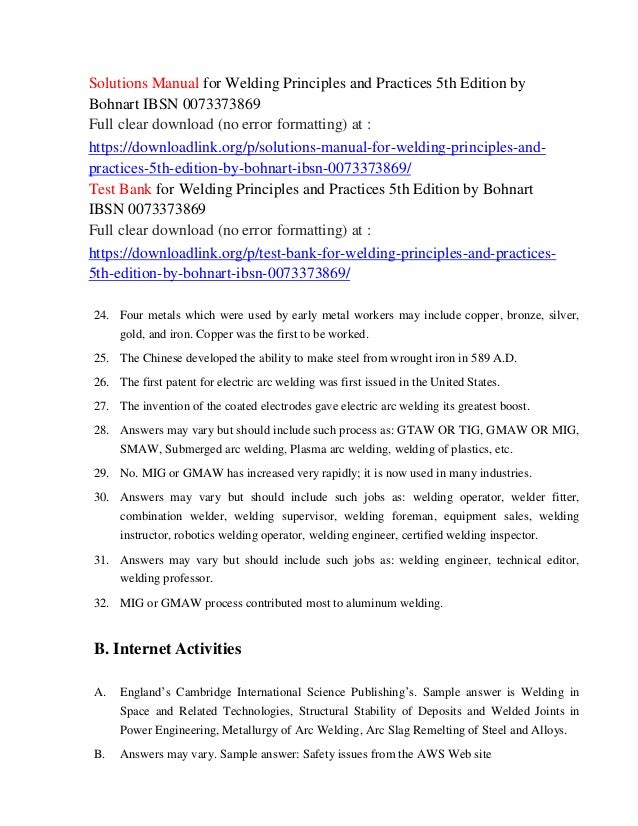

PDF Welding, Cutting, and Brazing Checklist Installation and Operation of Oxygen-Fuel Gas Systems for Welding and Cutting - 1910.253 Yes No Date corrected 1. Is acetylene generated, piped, or utilized at a pressure of 30 p.s.i. absolute pressure or less? .253(a)(2)? 2. Safety Practices In Welding Safety Practices In Welding Worksheet Complete the following study guide. Use the Safety Practices In Welding Packet Introduction Arc welding is a safe occupation when ___________________________ are taken to protect the welder from potential hazards. When these measures are overlooked or ignored, however, welders can encounter such dangers as PDF Quiz and Answer Key Welding Safety 13-026 - Family Insurance Center Answer Key - Welding Safety 13-026 1. Two of the more common types of welding are gas and shielded metal arc. True 2. The most common fuel used in OxyFuel Welding is acetylene. True 3. Shielded Metal Arc Welding joins two metals together by producing a laser arc between the base metals to be joined and a flux coated consumable electrode rod.

Welding shop safety worksheet. DOC Welding and General Safety Test - CTE Online In this shop there are: a) SMAW welders b) Oxy-Fuel welders c) GMAW welders d) All of the above 3. Safety glasses are to be worn in the shop… Always When you feel like it When sparks fly Only if they are in style 4. Any dangerous condition or injury to a person in the shop should be reported… When convenient At once At the end of class OSHA Welding Safety Equipment Checklist [Free] | SafetyCulture May 12, 2022 · A welding safety checklist is a tool used to assess workers’ safety throughout the entire welding, cutting, and brazing processes. It helps ensure compliance with regulatory standards including wearing of appropriate Personal Protective Equipment (PPE), welding equipment usage, and machinery inspections. Welding Safety Checklist Welding shop safety Flashcards | Quizlet Welding shop safety STUDY Flashcards Learn Write Spell Test PLAY Match Gravity Protective Click card to see definition 👆 To prevent cuts, a person should always wear the proper ________________ safety equipment. Click again to see term 👆 1/73 Previous ← Next → Flip Space THIS SET IS OFTEN IN FOLDERS WITH... Welding Shop Safety 20 terms PDF Arc Welder - ALCE Arc-Welding Safety and Operation Test Name_____ Date_____ Class_____ Multiple Choice - Place the letter of the most correct answer on the answer sheet. 1. When arc welding one should wear _____. a. wool clothing b. cotton gloves c. a heavy coat d. tinted glasses 2. For proper eye protection when arc welding the minimum shade number of the ...

Safety Resources - Lincoln Electric Safety Videos. Arc welding is a safe occupation when sufficient measures are taken to protect the welder from potential hazards. When these measures are overlooked, welders can encounter such dangers as electric shock, overexposure to fumes and gases, arc radiation, and fire and explosion. This video series is a powerful resource which keeps ... PDF Welding Safety Quiz - TAMU 1. Oxy Fuel Welding/Cutting Involves combining what of the following? A. Spark B. Oxygen C. Flammable Gas D. (A&C) E. (A,B, & C) 2. Arc Welding uses _____ to produce a spark/heat. A. High Voltage B. Welding Gas C. Flammable Gas D. (A&C) E. All of the above 3. Which of the following is not a general safety practice you should follow PDF Job Hazard Analysis Department: Welding Shop Welding Shop Date:, 2019 Possible Hazards or Task Describe Harm that could occur Hazard Rating (Low/ Medium/High) Control Action Personal Protective Equipment (PPE) Frequency of Monitoring Floor Jack Page 1 of 34 a) Pre-operation walk-around inspection. Clean any clutter surrounding machine and check for visible signs of wear. b) Place vehicle ... PDF Safety and Health guide | Welding Health and Safety Welding Health and Safety SS-832 | March 2015 Page | 5 Carbon arc cutting "arc gouging" is an arc cutting process in which metals to be cut are melted by the heat of a carbon arc. The molten metal is removed by a blast of air. This is a method for cutting or removing metal by melting it with an electric arc and then blowing ...

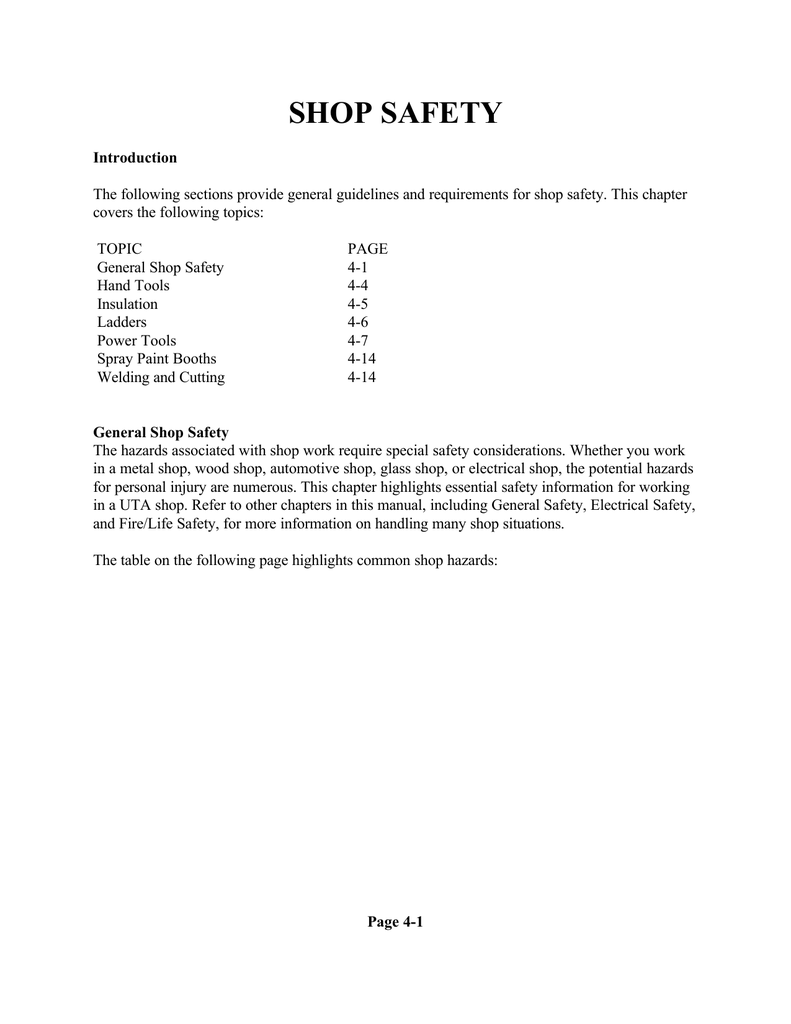

welding shop safety Flashcards | Quizlet fumes All types of welding and cutting operations produce some sort of gases. Gas pressure Alone can injure a person if its not used properly. high The potential for fire and explosions in the welding shop. Dangerous If two or more welders are working in close proximity to each other they need to be aware that their arc radiation ca be hurt others. Welding Safety Equipment Checklist | KMS Tools and Equipment KMS Tools has a great selection of welding helmets. We recommend auto-darkening welding helmets for both new welders and experienced pros. Since you don't need to flip them up and down between welds, auto-darkening helmets make it easier to produce consistent high-quality welds. They also eliminate neck fatigue caused by flipping traditional ... PDF SAFETY COMPLIANCE CHECKLIST Welding Operations ŸWelding materials requiring ventilation or air-line respirators: cadmium, fluorides, zinc, lead, beryllium, mercury, stainless steel (oxygen cutting using chemical flux or iron powder or gas shielded arc). ŸMaterials to be welded is not known? House- keeping ŸAre aisles marked? .22 ŸWidth of aisles maintained? .22 PDF Shop Safety Manual - Baylor University Shop safety rules are to be posted. 5. Horseplay is forbidden. 6. Machines are to be inspected prior to use. a. Machines should NEVER be used if all guards are not in place. b. Machines should be placed out of service if: i. Guards are missing or damaged ii. Machine is damaged or not operating properly

PDF Workshop Self Inspection Checklist (WELDING) WORK02 Workshop Self Inspection Checklist (WELDING) WORK02 Welding Areas and Operations Assessor Location Date This core checklist is provided by the Health and Safety Department as a template, which provides a basic framework for the conduct of a school self-inspection of the type of environment indicated.

Vocabulary Handout Welding Shop Safety.pdf - Welding Shop... s t ud e n t v o ca b u l a r y h a n do u t accompanies: welding shop safety 4welding shop safety lens shade number number indicating the level of darkness of lenses used in the welding and cutting industry; scale is from 1 to 14 with 1 being the lightest and 14 being the darkest source extraction ventilation ventilation system which extracts …

PDF Machine/Wood Shop Safety Inspection Checklist Proper eye protection in use Warning sign present for welding Adequate ventilation Cylinders kept separated Electric cables in good condition Gas piping in good condition Approved curtain or scre en in place All valves shut when not in use Other ____________________ CORRECTIVE ACTION TAKEN (indicate work order has been initiated)

PDF Safety & Health of Welders - Hobart Welding School Welder Dressed for Light Duty Welding 6. Welder Dressed for Heavy Duty Welding 7. Precautionary Information for Oxyfuel Gas Processes 8. Insulating Devices on Terminals of a Welding Machine 9. Welding Helmet 10. Eye Protection Filter Shade Selector 11. Welding Station Using Transparent Welding Screen 12.

PDF Machine and Machine Shop Safety Guide Environmental Health & Safety Office Machine and Machine Shop Safety Guide 07/2015 5 maximum opening of one-eighth (1/8) inch. • Before using abrasive wheel machinery, the wheel must be closely inspected for damages and a "ring test" should be performed. o Tap the wheel gently with a light nonmetallic implement, such as the handle of a

DOC Welding Orientation - Alma.Vocational.Welding Chapter 2, Safety in Welding Vocabulary worksheets Daily Shop Schedule 1. Good attendance is important, be in your seat and ready for class. 2. Check the chalkboard for specific instructions for the day. 3. Go to your welding booth and review work assignment. Check equipment and area for potential hazards. 4.

Shop Safety Teaching Resources | Teachers Pay Teachers This resource includes 12 common sense safety responsibilities (handout) for use when working in a shop class or any class that uses tools and machines. Also includes a safety test based on these rules. The test has 3 true/false, 2 fill in the blank, 7 short answer questions with different shop scenarios, and a poster to create.

Welding Shop Safety Worksheets - Learny Kids Displaying top 8 worksheets found for - Welding Shop Safety. Some of the worksheets for this concept are Shop safety, Arc welding safety guide, Safety health of welders, Basic shop safety t u d e t h a d o u t, Degrees that welding fabrication, Degrees that welding fabrication, Lesson plans for module 29101 15 w safety, Arc welder.

OSHA Welding Safety Requirements and Checklist The welding safety regulations described here center on hot work jobs such as welding, cutting, and brazing. These jobs can be hazardous, as they pose both physical safety and individual health risks. Half a million workers in a variety of industries are subject to illnesses and even fatal injuries.

PDF General Shop Safety - ALCE coats, etc. Shop clothing should not be loose, baggy or highly flammable. 2. Approved safety glasses must be worn at all times in the mechanics laboratory unless special eye or face protection is required. Approved safety glasses should be industrial quality. The Z 87.1 logo and the manufacturers emblem must be on the safety glasses for them to be

PDF Quiz and Answer Key Welding Safety 13-026 - Family Insurance Center Answer Key - Welding Safety 13-026 1. Two of the more common types of welding are gas and shielded metal arc. True 2. The most common fuel used in OxyFuel Welding is acetylene. True 3. Shielded Metal Arc Welding joins two metals together by producing a laser arc between the base metals to be joined and a flux coated consumable electrode rod.

Safety Practices In Welding Safety Practices In Welding Worksheet Complete the following study guide. Use the Safety Practices In Welding Packet Introduction Arc welding is a safe occupation when ___________________________ are taken to protect the welder from potential hazards. When these measures are overlooked or ignored, however, welders can encounter such dangers as

PDF Welding, Cutting, and Brazing Checklist Installation and Operation of Oxygen-Fuel Gas Systems for Welding and Cutting - 1910.253 Yes No Date corrected 1. Is acetylene generated, piped, or utilized at a pressure of 30 p.s.i. absolute pressure or less? .253(a)(2)? 2.

0 Response to "40 welding shop safety worksheet"

Post a Comment